Recipes, Recipe Cards & The Recipe Book

The recipe book is made up of recipes. You may create unlimited recipes. Recipe cards are generated from recipes. Recipe cards are used daily in Production.

Every item in the master item catalogue is linked to a recipe and it also has a scaling weight. We auto-populate the recipe book with all the names of the recipes that are assigned in the item catalogue, ready to create the recipe card, saving you time.

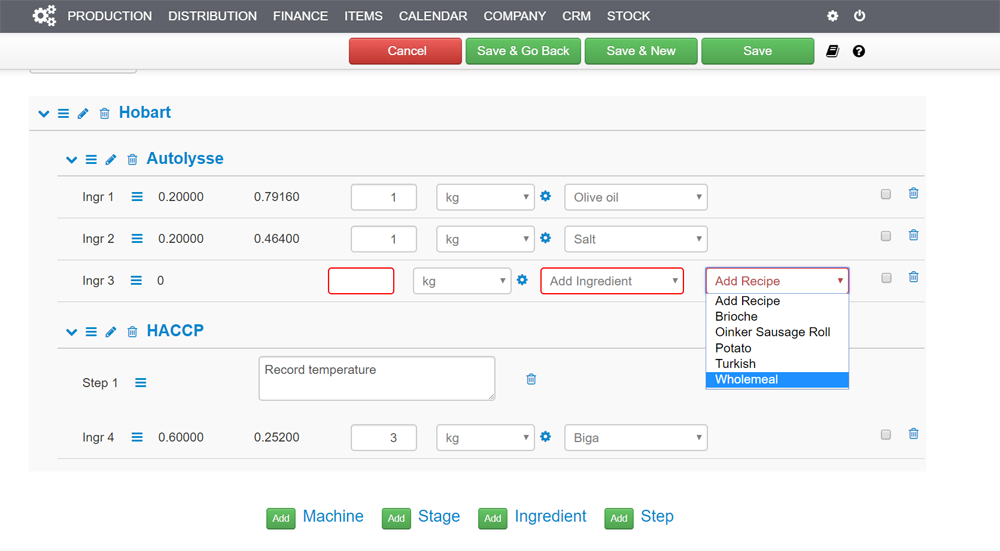

Recipes as ingredients: a recipe can be used as an ingredient in another recipe. For example, make a sourdough starter that is then used in various other recipes, or make a tomato sauce that is then used to assemble a pizza.

Recipe cards detail every item that must be made from the recipe, as well as any other recipes that call for the former one as ingredients.

As well as ingredients, recipe cards also have steps (instructions) which may be used for HACCP compliance. For example, recording temperatures at given points in the process.

An ingredient may be marked as foreign, meaning that it will not participate in the coefficients in the mix. For example, you may make a dough with flour, water and salt. Then, when the bread is formed, you will dab seeds on top. Seeds are added as a foreign ingredient.

Streamline automatically calculates costing for the recipe and therefore all items. Together with sales information, this is used to compute the gross profit reports by item and by customer.

Daily recipe cards are automatically created according to total orders. You may ‘mark -up’ the required yield by either a percentage or a fixed amount.

Total ingredients used are reported by quantity and cost and may be sorted either by vendor, ingredient group, location or alphabetically.

Ingredients

Units of Measure

We always suggest that you use the ingredient lot number in stock that has the nearest use by date. This may be over-ridden prior to marking the recipe card as ‘done’.

When marking the recipe card done, ingredients are depleted from stock and added to the shopping list. A lot number and use by date are assigned to the manufactured recipe. You may also record the temperature, in compliance with HACCP regulations.

Recipes also carry allergen information from the ingredients used.

You may set the total yield to be a percentage higher than that called for by the recipe.

The unit of measure that you stipulate for the overall mix, as well as the unit of measure that you stipulate for each individual ingredient, is the unit of measure that will be used in the recipe card.

If you want to see your recipe cards in grams, simply create the card in grams. Then, if you want to see, for example, water in litres, lbs or kgs, simply use that when adding the ingredient.

Trace ingredients by packing slip and recall goods with one click.

Machines

Create a list of production machines and their maximum capacity.

When making a recipe, a machine is required.

Depending on the capacity of the machine, recipes are broken down as necessary, when the total called for is greater than the machine’s capacity.

Example:

If the total needed is 300kg and the maximum capacity is 200kg, then the recipe will be broken down into 2 mixes, giving the option to

1. Mix two equal ones

2. One at the maximum capacity of 200kg and one at the balance of 100kg,

3. Manually enter each desired mix.